Caterpillar is pushing deeper into artificial intelligence by teaming up with Nvidia to embed advanced AI systems directly into its construction equipment. The move signals a major shift in how heavy machinery operates on job sites, where speed, safety, and real-time decision-making matter more than dashboards and laptops. By bringing AI to the machine itself, Caterpillar aims to help operators work smarter while reducing downtime and costly errors.

The partnership centers on a new AI-powered assistant being tested inside Caterpillar’s mid-size Cat 306 CR Mini Excavator. The system, known as Cat AI, runs on Nvidia’s Jetson Thor physical AI platform and is designed to function as an on-site digital companion for equipment operators. Instead of relying on manuals or remote support, operators can interact with the system while actively working, allowing them to make informed decisions without stepping away from the machine.

Cat AI operates through a collection of AI agents that work together to support the operator throughout the workday. These agents can answer operational questions, surface relevant machine data, provide safety guidance, and even help schedule maintenance or service checks. The goal is to reduce friction between the operator and the machine, making advanced insights available at the exact moment they are needed.

According to Brandon Hootman, vice president of data and AI at Caterpillar, this approach reflects how customers actually work. Operators spend their days in demanding environments, not behind desks. Because of that, Caterpillar focused on delivering insights directly into the workflow rather than pushing data to external systems that are rarely checked in real time.

A major advantage of deploying AI at the equipment level is the massive volume of data these machines generate. Caterpillar’s fleet sends back roughly 2,000 data messages every second, creating a continuous stream of operational intelligence. This data helps the company understand machine performance, operator behavior, and site conditions at a level that was previously impossible.

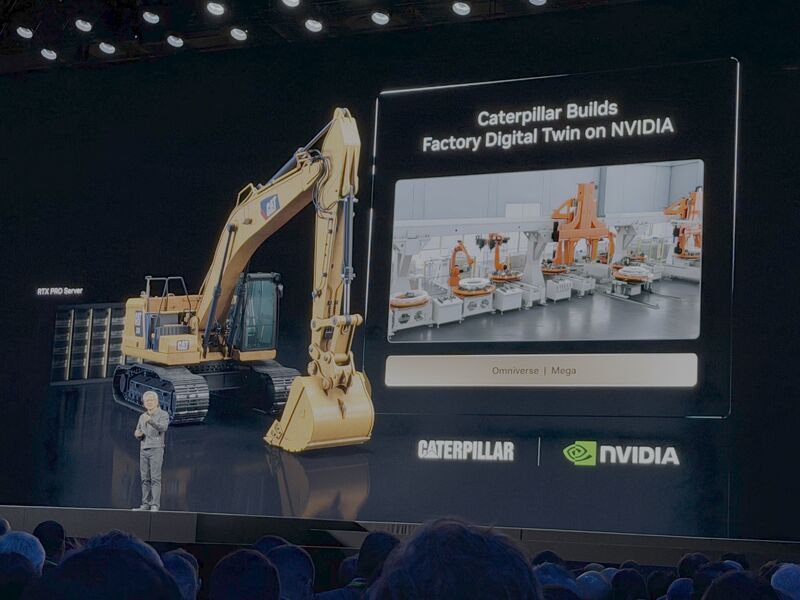

That constant flow of information also enables Caterpillar to experiment with digital twins of construction sites. Using Nvidia’s Omniverse simulation tools, the company is testing virtual replicas of real-world job sites to explore different scheduling scenarios and material requirements. These simulations allow teams to predict delays, reduce waste, and plan resources with far greater accuracy before work even begins.

Hootman explained that digital twins become far more powerful when fueled by live machine data. Instead of relying on assumptions, simulations can reflect real operating conditions. As a result, project managers gain clearer visibility into how decisions made today will impact timelines and costs tomorrow.

Caterpillar’s interest in automation is not new. The company already operates fully autonomous vehicles in its mining division, where controlled environments make automation easier to deploy at scale. However, bringing similar intelligence into construction equipment presents a much harder challenge due to unpredictable job sites and constant human interaction.

That difficulty is exactly why Caterpillar chose to begin with assistive AI rather than full autonomy. By starting with operator support, the company can address immediate customer pain points while building a technical foundation for future automation. This gradual approach allows Caterpillar to move faster without disrupting how work is done today.

From Nvidia’s perspective, the collaboration aligns perfectly with its broader push into physical AI. The chipmaker sees AI systems that interact with the physical world as the next major wave of innovation beyond chatbots and cloud software. Heavy machinery, vehicles, and industrial systems represent massive opportunities for AI to deliver real economic value.

Bill Dally, Nvidia’s chief scientist, previously described physical AI as a key growth area for the company. That vision was reinforced during Nvidia’s keynote at CES, where the company outlined a full-stack ecosystem designed to train, simulate, and deploy AI models in physical machines. This ecosystem includes open AI models, simulation environments, and developer tools built to accelerate adoption.

Nvidia’s leadership believes physical AI extends far beyond traditional robotics companies. Deepu Talla, vice president of robotics and edge AI at Nvidia, emphasized that nearly every industry is now building some form of robotics or intelligent machinery. From autonomous vehicles to construction equipment, the line between software and hardware continues to blur.

Talla described physical AI as the next wave of artificial intelligence, driven by powerful computers that can train models, simulate real-world behavior, and deploy intelligence directly into machines. In this vision, a Caterpillar excavator and a self-driving car share the same underlying AI principles, even if their use cases differ dramatically.

The Caterpillar partnership also highlights how legacy industrial brands are becoming key players in the AI landscape. While technology companies often dominate headlines, industries like construction, mining, and manufacturing offer some of the most impactful opportunities for AI adoption. These sectors deal with complex logistics, safety risks, and high operating costs, making them ideal candidates for intelligent automation.

By working closely with Nvidia, Caterpillar gains access to cutting-edge AI infrastructure while contributing real-world expertise that software companies often lack. This collaboration ensures that AI solutions are grounded in practical needs rather than theoretical possibilities.

The system’s public debut at CES underscores Caterpillar’s confidence in the technology. Demonstrating Cat AI on a live machine shows that the concept is already moving beyond experimentation. It also signals to customers that AI-driven construction equipment is no longer a distant idea but an emerging reality.

As Caterpillar continues refining Cat AI, the company plans to expand its capabilities across more machines and use cases. Each deployment generates additional data, which in turn improves models, simulations, and decision-making tools. This feedback loop positions Caterpillar to evolve its entire product portfolio around intelligence and automation.

The partnership ultimately reflects a broader transformation in industrial work. Machines are no longer just tools but intelligent systems that learn, adapt, and support human operators. By embedding AI where work actually happens, Caterpillar and Nvidia are redefining how construction sites operate and setting the stage for a more efficient, data-driven future.

This shift also changes expectations for equipment buyers. Contractors increasingly want machines that do more than move dirt. They want systems that help them plan, predict, and protect their workforce. AI-powered equipment delivers that value by turning raw data into actionable insight in real time.

As physical AI continues to mature, collaborations like this one will likely become the norm rather than the exception. The line between technology companies and industrial manufacturers is fading, replaced by shared platforms and joint innovation. For Caterpillar, the Nvidia partnership marks a decisive step toward that future, where intelligence becomes as essential as horsepower on every job site.